August 31, 2005

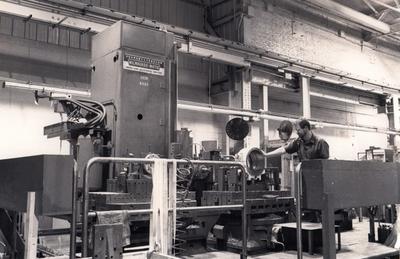

Beloit Corp and K&T Machining Center

I ran this K & T MilwaukeeMatic Machining Center from late 1989 to the end of 1995. (The longest time I spent doing the same job in my 21+ years at Beloit Corp. I think these were taken in something like 1990 or 1991?)

This machine had four 3' by 4' pallets where various jobs were preset/preloaded. You could have two pallets loaded to the machine at a time. In the photo above, you can see two jobs. I have my hand on a dryer bearing housing and there's a steamfit part ready to shuttle over and run.

One might wonder at the odd composition in these photos, but there was a reason. These photos were to supposed to be used in promotional materials, with accompanying videos at trade shows. The photos needed to obscure fixturing and machining methods while showing off our "modern" machining processes. I never did see the finished videos, but I think my dad got a surprise seeing his son in a video at a trade show. (Dad worked for Valmet/Metso, one of our competitors.)

In the next photo, you can just make out the "Automation Intelligence" control station, screen and keyboard. These were PC-based controls that were originally designed for Boeing. Beloit Corp purchased 4 of these in 1987 to retrofit onto all our K&T Machining Centers, replacing their out-of-date Allen-Bradley Controls. (Due to start-up issues we actually installed only 3 of the AI controls, saving the 4th for parts.)

The AI Control employed two motherboards, running 12 Mhz Intel 80286 processors, with 2 megs of RAM, sharing a single RLL 20 MEG hard drive, connected to a VGA monitor. (Lucky me, too! The first machine fitted got an - ugh, yech - EGA monitor!) One PC controlled machine motion/motors (MCP), while the other was the User Interface. The OS was IBM/MSDOS 3.3 with a primitive multitasker/shell interface called TASKVIEW. The AI control had a neat - and at the time unheard of - full-screen Wordstar-based Text Editor that was quite handy for tweaking our CNC programs.

That AI Control is a lot of the reason I ended up learning about PCs. It's what you might call the 'root' cause that sent me into the world of MS/DOS and PCs. So, in a weird sort of way, those controls continue to influence my life to this very day.

For those who think these machines just banged out thousands of the same thing day in and day out, that was not the case at Beloit Corp. Paper machines are custom made. This K&T alone had a library of well-over 10,000 programs for that many different parts. We called it a "long run" when we had more than 40 of the same part to machine.

And, yes, I still have an "I  DOS" bumper sticker from PC/Computing magazine in my desk downstairs.

DOS" bumper sticker from PC/Computing magazine in my desk downstairs.